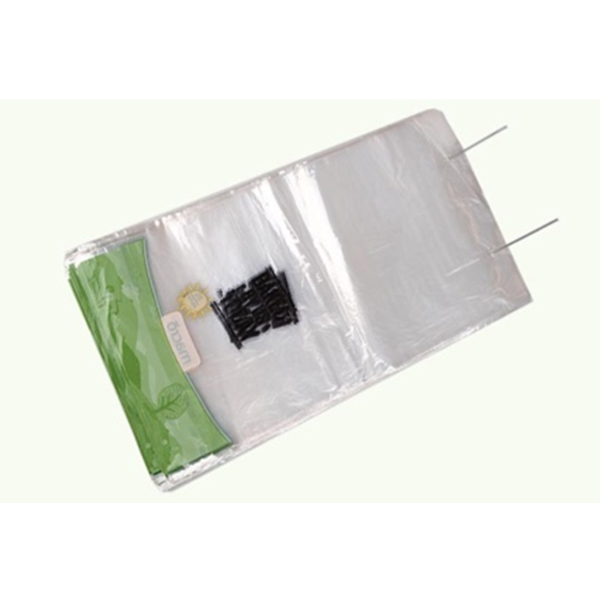

WICKET BAGS

High clarity wicketed plastic bags are packaged on a wire, generally in groupings of 100 to 250 bags. Wicket Bags are designed for use with automated packaging machinery, the wicketed bag is easy to use and efficient in Automatic, Semi-Automatic and Manual load applications. Side or bottom weld with two holes in the lip on a metal bar wicket. Some of the available are Reinforced headers, Header Seals, Bottom Gusset, flat bottom, perforated lip, vent holes, resealable tape strips, printing multiple colors of inks. Bags on wickets are a perfect consideration for Packaging and presenting anything from Bread or small mechanical Parts when being packaged in line or at work stations. An excellent way to close the bag is either heat sealing, being stapled, tied or taped shut.

COMMON USES

Bags for Inline Production, Bakery Bags, Agricultural Product Packaging, Hosiery Bags, Retail Product Packaging, Ice Bags, Apparel Bags, and much more.

Examples

Technical Specifications

| Dimension | Gauge | Custom Print | Air Holes | Vent Holes |

|---|---|---|---|---|

| Hang Hole | Die-cut Handle | Zipper Band | High/Low Slip | Header |

| UV Treated | Laminated | Perforation | ||

Types of material

| LLDPE (Virgin) | LLDPE (Recycled) | LLDPE (Tinted Blue) | HDPE | POLYPRO |

|---|---|---|---|---|

| POLYPRO (CAST) | LLDPE CoExtrusion | Shrink Film | Biodegradable Film | Compostable Film |